Laboratory Furniture: A New High-Performance Choice

In modern laboratory environments that demand high precision, cleanliness, and safety, selecting the right laboratory table is not only critical to work efficiency but also essential for operator safety and the longevity of equipment. Laboratory tables with aluminum-magnesium-silicon alloy frames are gradually replacing traditional wooden or steel tables due to their exceptional structural strength, corrosion resistance, and lightweight properties, making them the preferred choice for the next generation of lab equipment.

What is Aluminum-Magnesium-Silicon Alloy?

Aluminum-Magnesium-Silicon Alloy (Al-Mg-Si Alloy) is a heat-treatable alloy composed primarily of aluminum with added magnesium (Mg) and silicon (Si) elements. A typical representative of this alloy family is the 6000 series (such as 6061 and 6063), which is widely used across the aerospace, automotive, electronics, construction, and laboratory equipment industries.

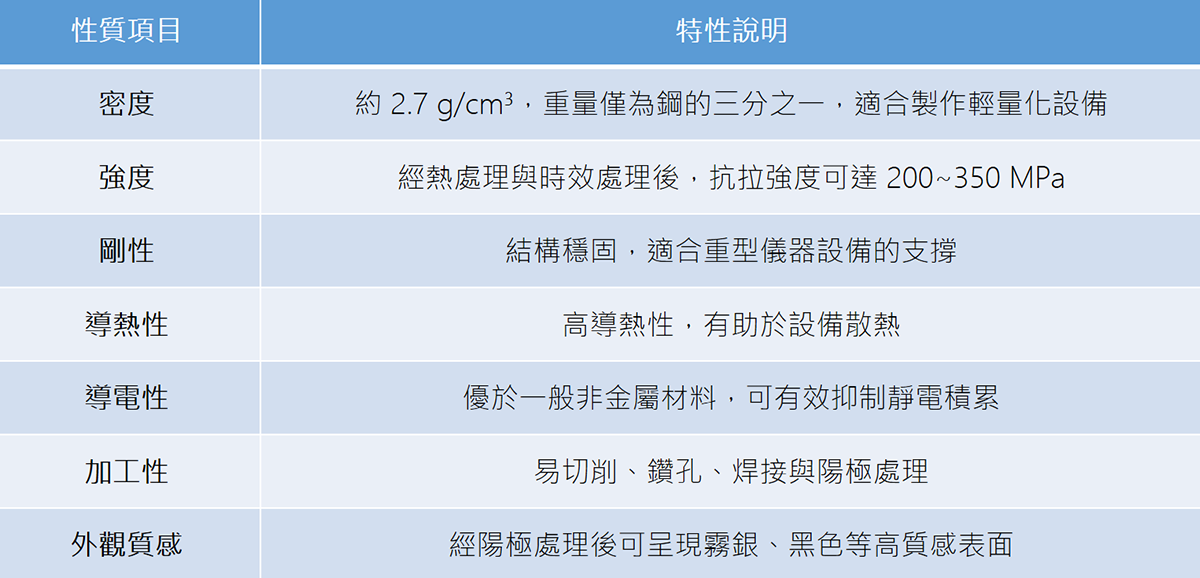

Physical Properties of Aluminum-Magnesium-Silicon Alloy

Why Choose Our Aluminum-Magnesium-Silicon Alloy Frame Laboratory Tables?

Applicable Industries and Application Scenarios for Laboratory Tables

-

Pharmaceutical/Biotechnology Industry: Cleanrooms, drug testing areas, GMP-compliant facilities

-

Semiconductor/Electronics Industry: Platforms for electrostatic-sensitive equipment, testing zones

-

Chemical Laboratories: Work areas for handling corrosive chemicals

-

Academic/Research Institutions: Laboratory platforms for teaching and research purposes

-

Food and Environmental Testing Agencies: Corrosion-resistant, high-cleanliness workspaces

Conclusion

Laboratory tables with aluminum-magnesium-silicon alloy frames not only meet the modern laboratory’s demands for structural stability, durability, and modular flexibility, but also offer unmatched advantages in aesthetics and corrosion resistance. Whether for new laboratory construction or upgrading existing facilities, these tables represent the ideal choice for both functionality and long-term performance.